Sustainable manufacturing with the TNC7

Software options for 6D setup support allow TNC7 users to probe fixtures and workpieces up to five times faster, thus saving considerable time and energy. Thanks to the non-stop monitoring of components and processes, along with extensive simulation capabilities, the TNC7 increases the process reliability of machine tools.

Information about the product

Click the plus signs to learn more about the product.

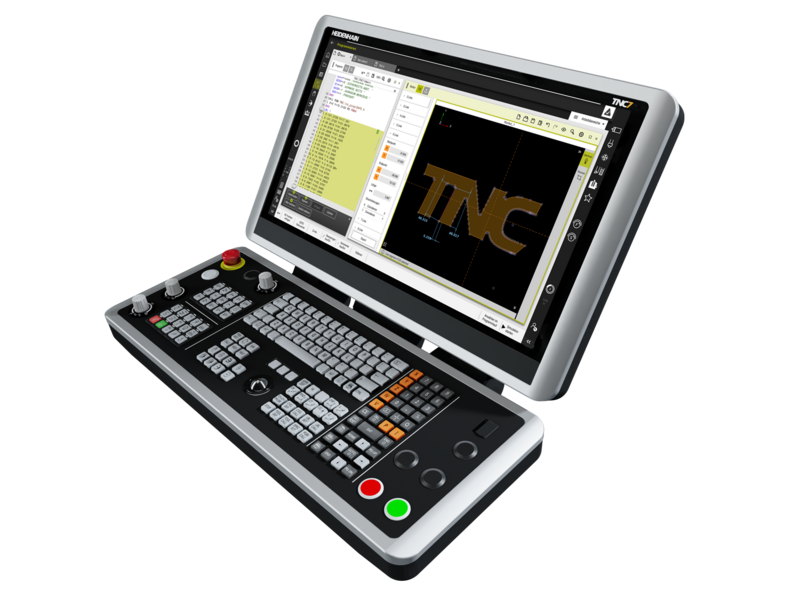

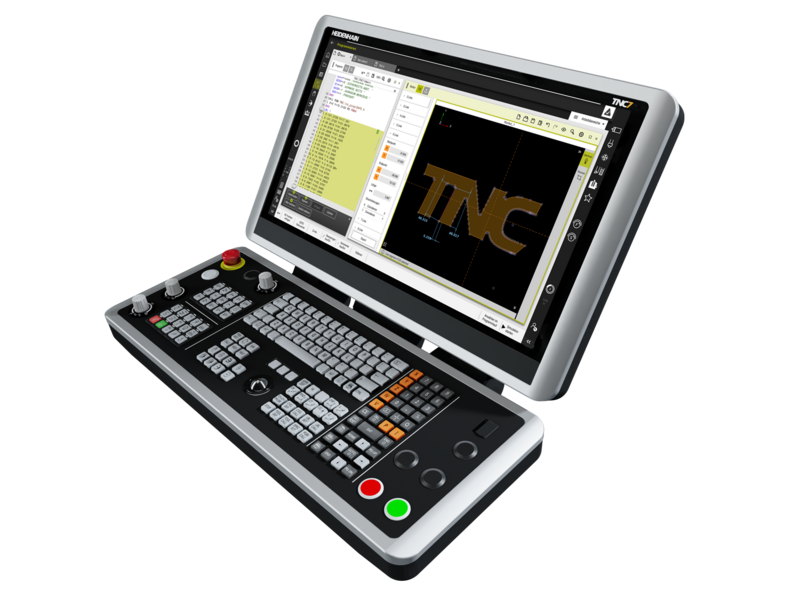

Touchscreen

Smooth and highly dynamic touchscreen operation ensures zero reaction delay with simple gestures such as are commonly used on mobile devices.

The operating panel

The newly developed keyboard features an improved mechanical design, including optimized key resistance. The improved ergonomics simplify your work and perfectly complement touch operation on the screen.

Customization

The screen workspaces can be adapted to individual needs and wishes. This includes, for example, favorites for NC functions, status notifications, and files, a home menu for getting started quickly, and personalized settings in the user administration function.

Intuitive programming

There are many options for creating a program at the control; a new one is the intuitive contour programming via symbolic gestures on the touchscreen. Klartext remains the main format for files and exporting, meaning that existing NC programs can continue to be used.

HEIDENHAIN TNC 7 | EN

03:37TNC7: Easy setup of any free-form surface with MAS option

03:37TNC7: Easy setup of any free-form surface with MAS option 05:34TNC7: Graphical Workpiece Measurement

05:34TNC7: Graphical Workpiece Measurement 03:19TNC7: Setup of Workholding Equipment

03:19TNC7: Setup of Workholding Equipment 02:54TNC7: Graphical Programming

02:54TNC7: Graphical Programming 03:19TNC7: Component Monitoring

03:19TNC7: Component Monitoring 03:00TNC7: Process Monitoring

03:00TNC7: Process Monitoring 13:33TNC7 Software Version 17 Webinar

13:33TNC7 Software Version 17 Webinar